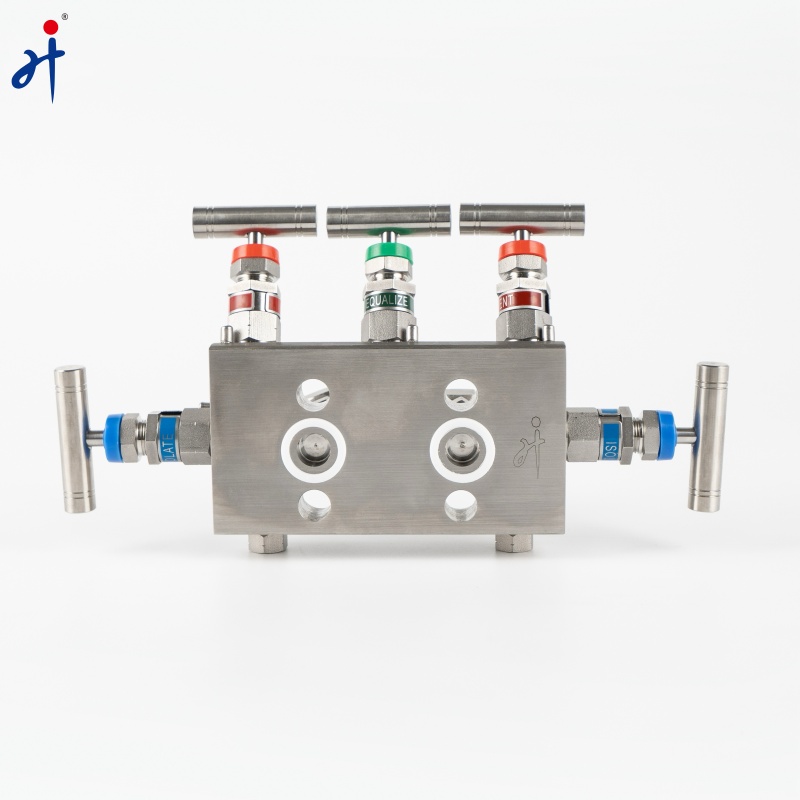

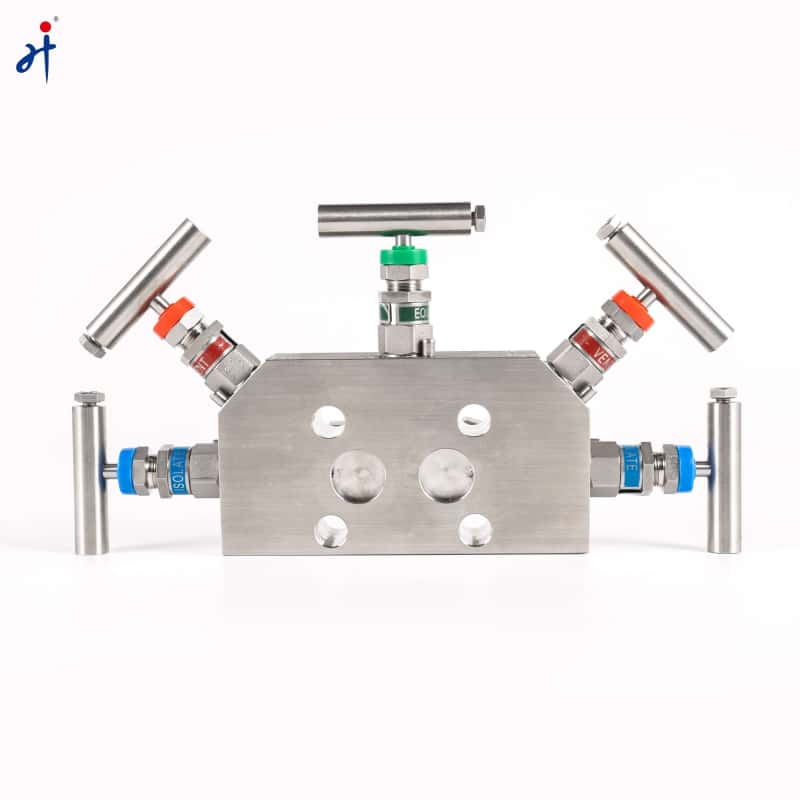

Integral five valve manifold combine several valves in one body with multiple connections. This equipment assists pressure instruments such as pressure gauges, pressure transmitters, and differential pressure transmitters directly and indirectly in measuring and equalizing pressures, differential pressures, static, gauge, and variable in process instrumentation lines by bleeding, blocking, and calibrating.

Typical Type Of Valve Manifold:

a. 2-Valve Manifold: For Pressure transmitters or gauges

b. 3-Valve Manifold: For Differential pressure transmitters

c. 3-Valve Manifold: For Differential pressure transmitters

d. Single Valve (Block): For Basic on/off control

Read More

- Email: sales01@hongjienterprise.com

- Tel: +86 15605507266

IPv6 network supported

IPv6 network supported